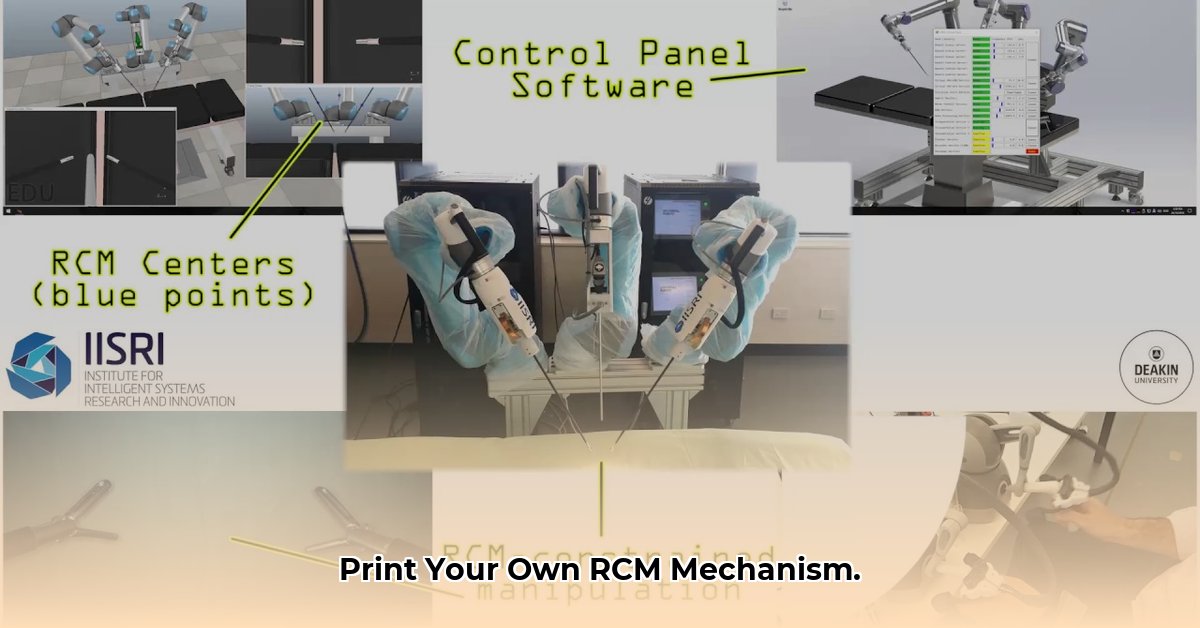

Understanding RCM Mechanisms

Remote Center Motion (RCM) mechanisms might sound complex, but the underlying principle is quite simple. Imagine your wrist: it rotates and pivots, but the center of that motion remains relatively fixed. That’s the essence of RCM! It’s about creating movement around a fixed point external to the mechanism itself, offering exceptional precision and control. RCM finds applications in diverse fields, from robotic surgery and camera stabilization to industrial automation and even some advanced 3D printers.

What Makes RCM So Special?

The “remote” center of rotation is the key to RCM’s effectiveness. This external pivot point allows intricate maneuvers within confined spaces without disturbing the surrounding area. For instance, in robotic surgery, an RCM allows the surgical instrument to move freely while the incision point stays perfectly still, minimizing trauma. This characteristic is also crucial in industrial robotics, enabling tasks like welding and painting with high accuracy and repeatability.

RCM vs. RCC: Understanding the Nuance

You might encounter the term “Remote Center Compliance” (RCC). While related, RCM and RCC are not interchangeable. RCM is the broader concept of motion around an external pivot, while RCC refers to devices designed with a specific type of spring-loaded RCM for specific compliance needs. Think of RCC as a specialized subset of RCM.

Designing and 3D Printing Your RCM

3D printing provides unparalleled flexibility in creating customized RCM mechanisms. Whether you need a specific size, unique shape, or unusual configuration, you can modify digital design files (STL files) and print exactly what you require. This on-demand fabrication is particularly beneficial for prototyping and experimentation, allowing for rapid iteration and cost-effective exploration of different designs.

Sourcing Your STL Files

Finding the right STL file is crucial. Several online repositories offer a plethora of RCM designs:

| Source | Description | Licensing |

|---|---|---|

| GitHub | A collaborative platform hosting open-source projects, ideal for finding customizable designs. | Varies, often open-source |

| Cults 3D | A marketplace for 3D models, offering both free and premium STL files. | Varies, commercial and non-commercial |

| Printables.com | A community-driven platform with a mix of free and premium STL files. User reviews and detailed descriptions can be especially helpful. | Varies, commercial and non-commercial |

| Yeggi | A search engine for 3D models, aggregating designs from various platforms, helpful for broadening your search. | Reflects the licensing of the source platform |

| Thingiverse | A large repository of 3D models, mainly focused on open-source and community-driven designs. | Varies, often Creative Commons licenses |

When selecting a file, consider:

- Degrees of Freedom (DOF): How many directions of movement do you need?

- Size Constraints: What are the maximum dimensions allowed for your project?

- Load Requirements: How much weight does the RCM need to support?

- Assembly Instructions: Does the file include clear instructions, diagrams, or videos?

- Required Hardware: Are there additional components (screws, bearings, springs) needed?

Some STL files allow for design modifications, enabling you to customize the RCM for your specific needs. This adaptability is a significant advantage of 3D printing, empowering you to create truly unique mechanisms.

Choosing the Right Material

Material selection is critical. Consider factors like:

- Strength: How much stress will the RCM endure?

- Flexibility: Does the application require flexibility or rigidity?

- Biocompatibility: Is the RCM for a medical application requiring biocompatible materials?

- Sterilization: Does the material need to withstand sterilization procedures?

Common 3D printing materials for RCM mechanisms include:

- PLA: A good all-around material, easy to print but less durable than other options.

- PETG: Offers better durability and temperature resistance than PLA.

- ABS: Known for its strength and impact resistance, but can be more challenging to print.

- Nylon: Provides excellent flexibility and wear resistance.

- Resins: Offer high detail and a wide range of properties, but often require specialized printers.

Ongoing research explores new printable materials optimized for RCM performance, suggesting that future options may offer even greater strength, flexibility, and biocompatibility.

3D Printing and Assembly: A Step-by-Step Guide

- Prepare Your Digital Design: Import the STL file into your slicer software. Configure settings like layer height, infill density, and support structures.

- Print Your Parts: Initiate the printing process, monitoring progress and making adjustments as needed. Print times vary depending on part size, complexity, and printer settings.

- Post-Processing: Remove support structures and smooth any rough surfaces. Sterilize parts if necessary for medical applications.

- Gather Hardware: Assemble the necessary hardware components (screws, bearings, springs, etc.).

- Assemble Your RCM: Follow the provided assembly instructions carefully. Pay close attention to component alignment and secure all connections.

- Test and Calibrate: Test the RCM’s range of motion, checking for smooth and precise movement. Address any stiffness, binding, or backlash.

Troubleshooting Common Issues

- Print Failures: Check bed adhesion, print temperature, and consider using a raft or brim for better adhesion.

- Ill-Fitting Parts: Verify scaling accuracy in your slicer. Minor adjustments may be necessary using a file or sandpaper.

- Stiff or Jerky Movement: Ensure bearings are correctly seated and lubricated (if required).

The Future of RCM and 3D Printing

Ongoing research in RCM design focuses on minimizing friction, reducing backlash, and improving load-bearing capacity. The ability of 3D printing to create complex geometries and incorporate diverse materials suggests that future RCM designs may exhibit enhanced performance characteristics. The exploration of compliant mechanisms, integrating flexibility directly into the design, represents a promising area of development. As 3D printing technology and material science advance, we can anticipate even more innovative and efficient RCM mechanisms in the years to come.

- Top Books on Meditation for Starting or Deepening Your Practice - February 7, 2026

- Top Rated Books on Mindfulness to Find Your Calm - February 6, 2026

- Top Rated Meditation Books to Deepen Your Practice - February 5, 2026