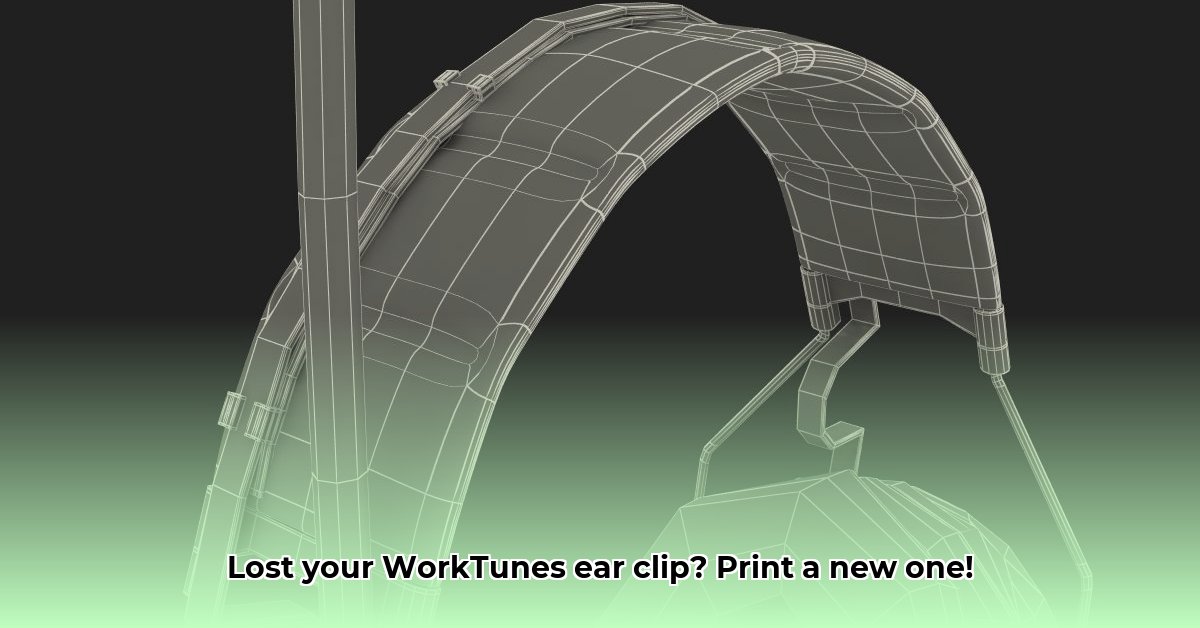

Download Free WorkTunes Ear Clip STL Files: Repair or Upgrade Your Headset. Lost or broken your WorkTunes ear clips? Don’t shell out for a new headset! This guide shows you how to 3D print replacements—potentially even better than the originals—from finding free designs to troubleshooting common printing issues. Whether you’re a 3D printing novice or a seasoned pro, get ready for comfortable ears and uninterrupted tunes.

Locate Your Perfect Ear Clip Blueprint

Your first step is finding an STL file, the digital design that tells your 3D printer what to create. While a dedicated, comprehensive repository for WorkTunes ear clip STLs doesn’t yet exist, several avenues are worth exploring.

Where to Search for STL Files

- Thingiverse: https://www.thingiverse.com/ A popular platform for sharing 3D printable designs. While finding a perfect match might require some searching, it’s a good starting point.

- STLFinder: https://www.stlfinder.com/ A search engine specifically for 3D printable models. Using relevant keywords like “WorkTunes ear clip” or “hearing protection accessories” may yield results.

- Yeggi: https://www.yeggi.com/ Another search engine for 3D models, aggregating results from various sources. It allows you to filter by price and license, helpful for finding free options.

(Include screenshots of search results on these platforms)

What If You Can’t Find the Perfect File?

- Adapt an Existing Design: If you find a similar ear clip design, you may be able to adapt it to fit your WorkTunes with some modifications in a CAD program.

- Reach Out to the Community: Online 3D printing forums and communities can be invaluable resources. Someone may already have the file you need or can offer design assistance.

- Design Your Own: If you’re comfortable with CAD software, designing your own clip allows for complete customization. This might seem daunting, but many free and paid CAD programs offer tutorials and resources.

- Contact 3M/WorkTunes: While unlikely to provide an STL file directly, they might offer replacement parts or dimensional information that could inform a custom design.

Select the Right Filament

Choosing the right filament is crucial for comfort and durability. It’s akin to selecting the right type of wood for furniture—each material has its strengths and weaknesses.

Filament Options and Considerations

- PLA (Polylactic Acid): Easy to print and environmentally friendly, but can be brittle. Not recommended for ear clips due to its rigidity.

- ABS (Acrylonitrile Butadiene Styrene): Strong and impact-resistant but can be tricky to print and emits potentially unpleasant fumes. Likely overkill for ear clip flexibility needs.

- TPU (Thermoplastic Polyurethane): The recommended choice. Flexible, durable, and comfortable against the skin. While potentially more challenging to print, its flexibility makes it perfect for long-term wear. Within TPU, different Shore hardness levels exist; a softer TPU (70A-90A) is generally preferred for ear clips.

- PETG (Polyethylene Terephthalate Glycol): A good balance of ease of printing and durability, but can be prone to stringing. Not as flexible as TPU but worth consideration if TPU proves too challenging.

(Include a table comparing filament properties: Durability, Flexibility, Print Difficulty, Comfort)

Prepare for 3D Printing

Before you begin printing, proper preparation is essential for a successful outcome.

Software and Slicer Settings

- Slicer Software: Use a slicer program (e.g., Cura, PrusaSlicer) to convert the STL file into G-code, the language your 3D printer understands.

- Orbitr Recommendation: Orbitr, a common WorkTunes ear clip design, frequently suggests vertical printing and 100% infill for optimal strength. Vertical printing builds layers for strength, while 100% infill ensures a solid, durable clip.

Printer Setup

- Bed Adhesion: Ensure proper bed adhesion to prevent the print from warping or peeling off during the process. This may involve using a heated bed, adhesive, or specific bed materials.

- Leveling: A level print bed is essential for a successful print, preventing uneven layers and potential adhesion issues.

(Include screenshots of slicer settings)

Print Your Ear Clip

Now for the main event!

- Import: Import the sliced G-code file into your 3D printer’s software.

- Verify Settings: Double-check orientation, infill, and other settings before starting the print.

- Print: Start the printing process.

- Cool Down: Allow the print to cool completely before removing it from the bed to prevent warping or damage.

(Include step-by-step photos of the printing process)

Post-Processing (Optional)

- Support Removal: If supports were used, carefully remove them.

- Sanding: Smooth any rough edges or imperfections with sandpaper.

Troubleshooting

- Warping: Adjust bed temperature, use an enclosure, or improve bed adhesion.

- Stringing: Modify retraction settings or try a different filament.

- Failed Prints: Check filament quality, nozzle temperature, and bed adhesion. Online 3D printing communities can offer targeted advice.

Design Considerations and Modifications

Ear anatomy, sound quality, and comfort are key considerations.

Design Features

- Comfort: Shape, size, and material flexibility all contribute to comfort.

- Noise Reduction: Some designs incorporate features to minimize external noise.

- Audio Quality: Certain shapes may impact sound delivery. Research suggests specific modifications could potentially enhance audio quality, but this is an area of ongoing study.

(Include a table showcasing different hypothetical ear clip designs and their features: Comfort, Noise Reduction, Durability, Ease of Printing, Material Recommendations)

Community and Resources

Share your designs and experiences within the 3D printing community. Collaboration fosters innovation and helps others troubleshoot issues. As the community grows, a dedicated repository of WorkTunes ear clip designs may emerge, simplifying the search process for everyone.

Conclusion

3D printing offers a cost-effective and customizable solution for replacing WorkTunes ear clips. By following this guide and engaging with the 3D printing community, you can create comfortable, durable, and personalized ear clips, extending the life of your headset and enjoying uninterrupted tunes. This project is just one example of the vast potential of 3D printing—explore and discover what else you can create!

- Essential Meditation Books for Beginners to Deepen Your Calm - February 12, 2026

- Top Meditation Books for Beginners to Begin or Deepen Your Practice - February 11, 2026

- Best Books About Mindfulness Meditation for Every Journey - February 10, 2026