Achieving visually impressive and structurally sound concrete requires selecting the right form liner. Fractured fin liners, known for their textured finish that mimics natural stone, are a popular choice. This comprehensive guide covers everything from pattern types and materials (ABS, STY, and Urethane) to cost analysis, installation techniques, and sustainable practices. Whether you’re a seasoned construction professional or a dedicated DIYer, this guide will empower you to make informed decisions, optimizing both the aesthetic appeal and budget of your project.

Exploring Fractured Fin Concrete Forms

Fractured fin concrete form liners are specialized tools designed to impart a highly desirable, natural, and textured finish to concrete surfaces. They transform ordinary concrete into architectural features that evoke the beauty of natural stone. Beyond mere aesthetics, selecting the appropriate liner is a critical factor affecting the overall success and cost-effectiveness of your project.

Dissecting Fractured Fin Patterns: A World of Textural Possibilities

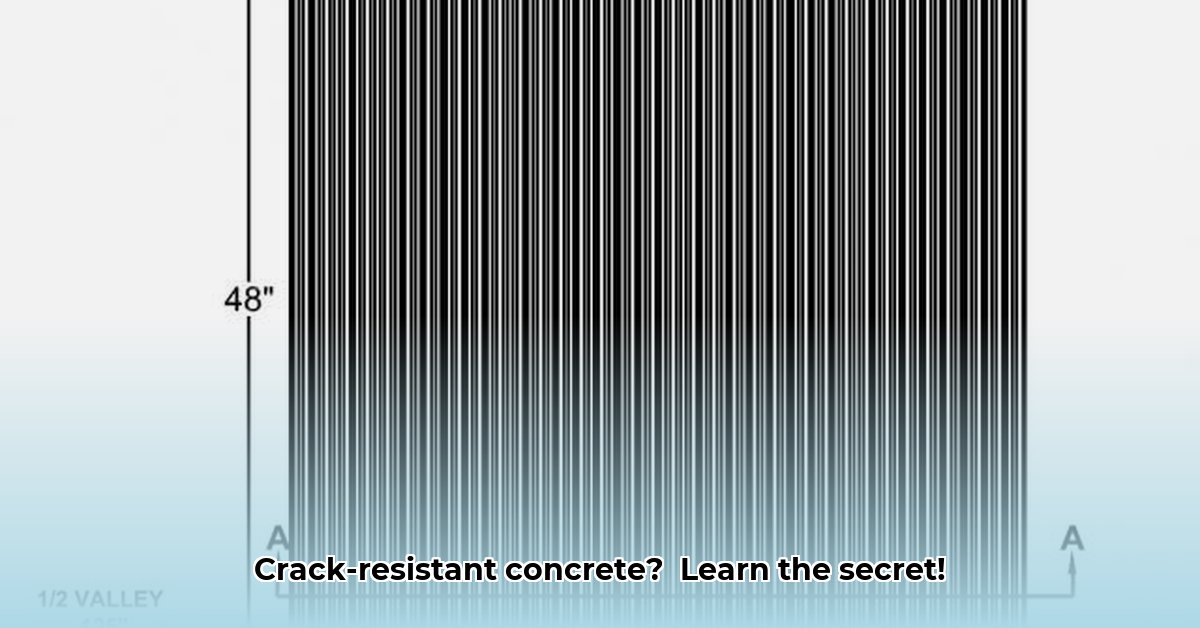

Fractured fin liners work by pressing a patterned mold into wet concrete, creating a variety of textured surfaces. The pattern variations arise from several key factors:

- Fin Dimensions: The relief (fin height), peak height (the highest point of the fin), and rib spacing (distance between fins) drastically impact the final texture. Closely spaced, high-relief patterns create a bold, dramatic look, while wider, lower-relief patterns provide a more subtle, nuanced effect.

- Material Composition: Liners are typically manufactured using ABS (acrylonitrile butadiene styrene), STY (polystyrene), or urethane. Each material offers a different balance of cost, durability, reusability, and environmental impact. Selecting the right material is crucial for project success.

Material Selection: ABS, STY, and Urethane Compared

Choosing the correct material—ABS, STY, or Urethane—requires carefully considering durability, cost, and reusability. Each material suits different project needs and budgets.

| Feature | ABS | STY | Urethane |

|---|---|---|---|

| Durability | High; withstands numerous pours, ideal for long-term use. | Moderate; suitable for fewer uses, shorter lifespan. | Very High; designed for repeated use in demanding conditions. |

| Reusability | Excellent; maintains pattern integrity over many uses. | Good; may show cracking with repeated use, affecting pattern quality. | Exceptional; provides a consistent finish over hundreds of pours. |

| Cost | Higher upfront investment; reflects material quality and durability. | Lower initial cost; budget-friendly for short-term or limited-use projects. | Highest initial investment; minimized long-term costs due to extreme durability. |

| Environmental Impact | Higher manufacturing footprint; explore recycling options. | Lower manufacturing footprint; easily recyclable. | Varies by formulation; inquire about low-VOC and recycled content options. |

| Weight | Heavier; requires robust handling equipment. | Lighter; simplifies transportation and handling. | Moderate; balances durability and ease of handling. |

The ideal choice depends on the specific requirements of your project. ABS is a strong choice when durability and repeated use are important. STY is an economical option for budget-conscious or single-use projects. Urethane is typically specified for large projects where the forms are used repeatedly. Understanding these differences helps in effective project planning.

Cost Analysis: Understanding the Investment

The cost of fractured fin liners varies depending on several factors:

- Material Type: ABS and Urethane liners are generally more expensive than STY due to their enhanced durability and potential for reuse.

- Pattern Intricacy: Complex designs require precise manufacturing techniques, leading to higher costs.

- Manufacturer Reputation: Established manufacturers with a reputation for quality may have higher prices. Comparing multiple supplier quotes is crucial.

- Project Size: Larger projects may qualify for bulk discounts, reducing the per-unit cost.

Contact manufacturers directly for accurate pricing. Remember to consider the total cost of ownership, including the potential for reuse and the lifespan of the liners.

Installation Guide: Best Practices for Optimal Results

Proper installation is crucial to achieving the desired finish and maximizing the lifespan of your fractured fin liners:

- Form Preparation: Ensure forms are clean, level, and free of debris before applying liners.

- Liner Attachment: Securely fasten liners to the formwork using appropriate adhesives or mechanical fasteners, following manufacturer recommendations.

- Release Agents: Apply a high-quality release agent to the liner surface to facilitate easy form removal and prevent damage.

- Concrete Placement: Pour concrete carefully, avoiding excessive vibration that can damage the liners or compromise the pattern.

- Curing Process: Follow standard concrete curing practices to ensure proper hydration and strength development.

- Form Removal: Remove forms gently to prevent damage to the concrete surface and the liners.

Navigating Regulations and Sustainability

Building codes and regulations regarding concrete form liners vary by location. Always verify compliance with local building authorities before starting your project. Increasingly, sustainable building practices are also important.

- Material Selection: Opt for liners made from recycled materials or those that are easily recyclable.

- Waste Reduction: Minimize waste by carefully planning your project and ordering the correct quantity of liners.

- Extended Lifespan: Choose durable liners that can be reused multiple times, reducing the need for replacements.

Selecting the Right Fractured Fin Liner: A Checklist

Choosing the correct liner requires balancing budget, aesthetics, project-specific requirements, and regulatory compliance.

* Define your budget.

* Assess project requirements.

* Research and compare patterns.

* Prioritize safety.

Ongoing research into new materials and sustainable practices can further optimize your choices.

Comparing Liner Prices: A Strategic Approach

Key Takeaways:

- Material choice significantly impacts price: ABS, STY, and urethane offer different cost-benefit ratios.

- Pattern complexity affects manufacturing costs: intricate patterns command higher prices.

- Manufacturer reputation matters: established brands may charge more for quality assurance.

- Project scale enables volume discounts: large projects benefit from economies of scale.

- Total cost of ownership is crucial: factor in reusability, maintenance, and lifespan.

Understanding Pattern Variations

Fractured fin concrete form liners create textured surfaces on poured concrete with various patterns. Fin dimensions include relief (height), peak (sharpness), and rib spacing. Materials range from ABS plastic (affordable, limited reusability) to STYROFOAM (lightweight, lower durability) and high-grade urethanes (expensive, highly reusable).

Material Comparison: Making Informed Choices

Choosing the right material is essential. Consider the following comparison:

| Material | Durability | Reusability | Cost (Estimated) | Environmental Impact |

|---|---|---|---|---|

| ABS | Moderate | Moderate | Moderate | Recyclable, but energy-intensive production. |

| STYROFOAM | Low | Low | Low | Difficult to recycle; potential for environmental persistence. |

| Urethane | High | High | High | Varies by formulation; seek supplier environmental data on VOC content and recyclability. |

Deciphering Cost Factors

Several elements drive the cost of fractured fin concrete form liners. Material choice is substantial, as is pattern complexity. Manufacturer reputation influences pricing, and bulk purchasing lowers unit costs. Shipping and handling fees also contribute.

Installation Guidelines

Securely fasten liners to formwork to prevent shifting during concrete placement. Closely follow manufacturer instructions and prioritize safe handling practices. Consult experienced professionals for large-scale projects.

Regulatory Compliance Matters

Building codes related to liners vary. Before selecting materials and patterns, check with local authorities for compliance, covering material safety, fire safety, and dimensional tolerances.

Budget-Conscious Pattern Selection

Key Takeaways:

- Fractured fin patterns offer design flexibility at various price points.

- Material choices (ABS, STY, urethane) influence cost and performance.

- Pattern dimensions, reusability, and environmental impact require careful consideration.

- Vendor diversity indicates a competitive market: compare quotes from multiple suppliers.

- Customizable design options cater to diverse needs and budgets.

Exploring Concrete Form Liners

Fractured fin concrete form liners are molds used to create textured concrete surfaces, offering design flexibility. They add visual interest to walls and columns. Choose the right one considering key aspects.

Pattern Types: A Detailed Overview

Pattern variations involve:

- Fin Dimensions: The relief, peak, and rib spacing contribute to unique visual effects. Larger patterns increase costs but enhance visual impact.

- Materials: ABS (durable, reusable, pricier), STY (budget-friendly, less durable), and urethane (long lasting, highest upfront cost).

- Pattern Complexity: Simple designs are cheaper; intricate patterns are more expensive.

Material Comparison: Budget and Performance Trade-offs

The choice between ABS, STY, and urethane affects your budget.

| Material | Durability | Reusability | Cost | Environmental Impact |

|---|---|---|---|---|

| ABS | High | High | High | Recyclable |

- The TM Book Offers an Essential Guide to Meditation. - March 4, 2026

- Transcendental Meditation Books Guiding Your Journey to Deeper Practice - March 3, 2026

- Your TM Meditation Book Explores Its Benefits and History - March 2, 2026